Do you ever wish you could just press a button and instantly receive ammunition? Of course you do. We’re still a long way off from Star Trek replicators, but a home reloading setup is about the closest thing the gun world has to that kind of sci-fi technology. With a workbench and some equipment, you can custom-make your own ammunition to fit your exact use case. It isn’t as simple as pressing one button, though; there many factors to consider before you take the plunge and begin “rolling your own.” During my time tweaking my own reloading setup and comparing notes with others who do the same, I’ve picked up a few tips and tricks that more people should know going in.

Start With the Books

One of the most important parts of any reloading setup is a good manual, or better yet, a bookshelf full of them. Remember, you’re playing around with highly combustible materials, so you need to have a firm grasp of the science and engineering that go into making good, safe ammo. Before you even begin looking at presses and tumblers, you should go out and buy at least two reloading manuals. I have a Hodgdon 2022 Annual Manual and the massive Lyman 51st Edition; every major producer of tools and components publishes their own. Don’t think you can get by with the little chart on the bottle of gunpowder—any proper reloading manual will include a wealth of information and technical specifications that don’t fit neatly on a label the size of a cocktail napkin. Having more than one allows you to cross-check load data and cover a wider range of components.

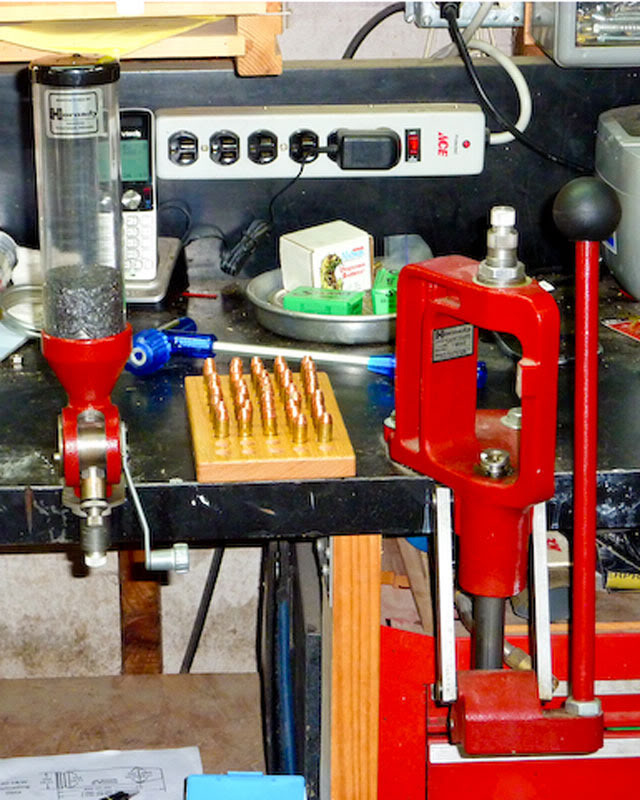

You Need Lots of Equipment

In many hobbies, the main allure of doing your own work is that it’s a great way to save money. Manufacturing ammunition isn’t the same as doing an oil change, though; it requires a substantial initial investment into some very specialized hardware. The reloading press itself only accounts for a fraction of the total upfront cost of building a DIY ammo factory in your basement or garage, even if it comes as a kit with all the accessories included. For advice, I consulted my good friend Doug, a long-range shooter who loads all his own ammunition for maximum precision. He pointed out that many beginners don’t realize “how much equipment you really need to make good, reliable, and consistent ammo.” Before you can get started measuring powder and seating bullets, you’ll need to spend a significant amount of time cleaning and resizing the fired cartridge cases, a complex process which requires several different machines that all cost money and take up space. “It’s much more than just a good press,” Doug said.

It Isn’t Necessarily Cheaper

Once you’ve shelled out hundreds or even thousands of dollars on all the equipment, you’ll need to make it pay for itself. For value analysis, I put together a handy little spreadsheet that analyzes my expenses. You can do the same math on the back of an envelope: for each different cartridge you shoot, determine the average cost of components for each round, then subtract it from the price per round if you were to buy it at a store. Multiply that number by the number of that type of round you shoot in a given time period (per month or per year). Whichever cartridge yields the highest result is the most cost-effective one for you to reload. 9×19 is usually a waste of time and money because it’s so cheap to buy that it would cost you almost the same or even more to load your own. I reload .38 Special not just because I shoot a lot of it, but also because the components are so cheap that each round I make puts about a dime toward paying off my equipment. As a precision shooter, Doug would have to pay through the nose to buy the type of premium match-grade ammunition he makes at home: commercial 6.5-284 Norma starts at $50 for a box of 20.

Be Patient

Reloading is a niche hobby for a reason; if it was easy, everyone would do it. It takes time and practice to get to know your equipment and dial in your load. Chances are, your first batch will be rife with defective rounds, and even the ones that go “bang” still won’t be perfect. Perfection requires iteration, and iteration requires a methodical approach and a willingness to put in the work. Don’t stress out about early problems, just learn what works and what doesn’t and hone your technique from there. It takes work, but reloading can be a relaxing experience with a rewarding outcome. Few other shooting experiences provide the kind of satisfaction that comes from hitting the target with ammunition you made all by yourself.

Getting into reloading is a big undertaking with a substantial startup cost, but don’t let that discourage you. If you have a good workspace available and the commitment to see a project through, go for it! Hopefully the information in this admittedly long-winded blog post will help you avoid some easy beginner mistakes and put you on the right track toward developing the perfect load.